- Home

- Services

- Products

- Applications

-

Sustainability

Sustainability

- Company

- Contact

-

-

As a unique mineral, graphite also requires unique handling and attention. As the world’s leading specialist for graphite with decades of experience, we can guarantee that the entire value chain comes from one single source – from mining to packaging and delivery of the final product, from technical consulting to the development of ground-breaking innovations for the applications of tomorrow.

Company mines in Europe and Asia not only ensure the secure supply of graphite to our customers, they also maintain a consistent level of raw material quality – a parameter we monitor meticulously. AMG Graphite has its own purification systems in Germany and uses an array of special grinding processes, selected based on the intended application and customer requirements. The latter also governs the choice of packaging unit, whether paper bags, big bags or silo trains.

The majority of the raw materials for AMG Graphite’s products stem from company mines. Thanks to secure raw material sources in Asia and Europe, we can guarantee our customers the highest security of supply paired with consistently high product quality. We extract graphite from underground mines at our company headquarters in Kropfmühl and in Sri Lanka.

In order to enrich graphite as a concentrate, the crude ore is wet extracted and subjected to flotation. This process separates the graphite from other minerals by wet mechanical means to achieve a carbon content of to up to 98 percent. After this graphite has been dewatered, dried and sieved as well as separated into different fractions, the refined raw material is ground to various grain sizes – with some of the graphites going down to sizes of less than 2 micrometres. Various grinding processes also influence the particle morphology, optimise the particle size and give the graphite its desired shape.

Further processing steps are necessary after flotation for products with a graphite content of more than 98 percent. In the chemical purification process, the carbon content of the graphite is increased once again and a purity of more than 99 percent is achieved. Chemical/thermal purification even makes purity levels of up to 99.99 percent possible.

Industrial processes require complete transparency and the maximum available customisation. AMG Graphite delivers everything from one single source, manages and controls all process steps, and can draw on many years of experience and expertise in the international graphite business. Our services unlock new value creation potential along the production and supply chain, boosting operational efficiency, product quality and profitability. AMG Graphite offers its customers and partners a unique and consistent range of identification and localisation systems for all products and processes. Our Chinese subsidiary QKG bolsters the raw materials network in Asia, ensuring the selection and monitoring of suitable graphites, and operating in step with German quality standards.

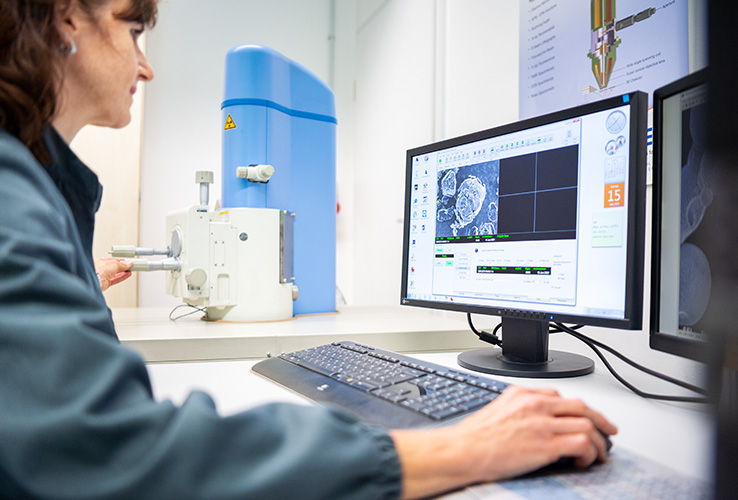

AMG Graphite ensures the continuous optimisation of its product portfolio with far-reaching research and development work. Based on cutting-edge and quality-focused processes, we develop high-quality custom solutions and special products in dialogue with our customers and partners. AMG Graphite stands out as a leading technological company thanks to its intensive work on new processing techniques and development of special graphite products for modern applications. By cooperating regularly with universities and research institutions in the long-term, we are committed to fostering the transfer of knowledge and playing a leading role in pioneering projects.

Thanks to its large standard product range, AMG Graphite is well positioned to respond to any requirement in a customer-oriented and flexible manner. This is our core competence. In order to offer our customers and partners the best solutions, in-depth knowledge of their processes, use cases and final applications is needed – and this in turn demands great mutual trust. Thanks to our diverse product portfolio and decades of experience in a wide range of industrial sectors and areas of application, we are built to provide customers with outstanding technical advice. In this respect, the AMG Graphite Group helps to improve and optimise processes – and in doing so helps customers bring high-end products to market.

Thanks to its 2D crystal structure consisting of only one layer of carbon atoms, graphene has the potential to revolutionise microelectronics and computer technology based on its supreme electrical conductivity. If screens and mobile phones can soon be folded like a newspaper, cars can drive by themselves, planes weigh only a few kilos and people can soon jet off to Mars, then graphene will undoubtedly have a role to play – and AMG Graphite’s product portfolio will likely be at the forefront of this development. Graphene is just one of many innovations in our sights. Open to any new development, we are the perfect raw material partner for forward-looking ideas across all industries, supporting customers in ground-breaking innovations and patenting ideas.